INNOVATION

Programmable Multibeam technology

Why use only one beam when you can have hundred ?

VULQ1 laser solutions are designed for high-throughput precision material processing applications in industrial environment, like laser marking and micromachining

They are based on a simple yet powerful idea :

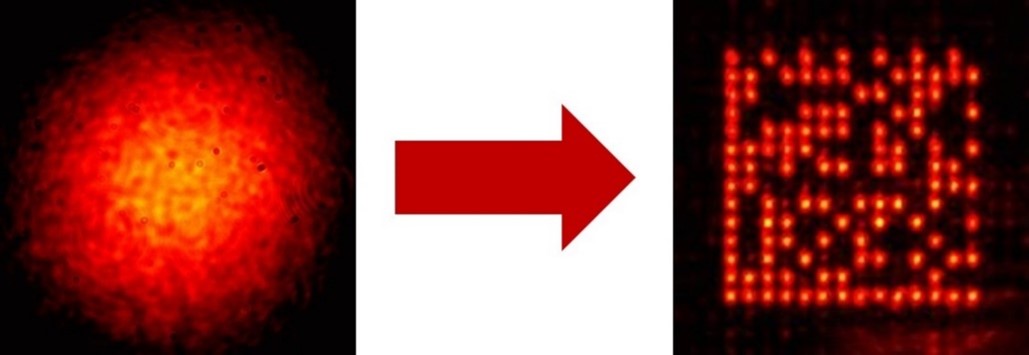

In the laser world, “adapting the tool” means shaping the laser beam in such a way that it benefits the target process ; we call the shaped laser beam a “Laser Light Tool” (see fig.1)

Laser beam shaping is achieved with Spatial Light Modulators (SLM), nowadays a mature technology for industrial use. Compared to other beam shaping technologies (DOE, MEMS, MDM), SLMs have the advantage of higher efficiency and finer dynamic control (see fig.2).

All these capabilities are embedded in VULQ1 programmable multibeam technology, the core technological platform behind the VULQ1 solutions.

There are two main applications of dynamic laser beam shaping for precision material processing :

Flexible parallelization of process

working with several beams simultaneously multiplies throughput for precision material processing applications. A fast dynamic reconfiguration capability is critical for effectively delivering value in real-life applications.

Beam quality control

controlling the laser beam profile is essential to maintain optimal operation conditions along the production system lifetime, particularly for high-resolution applications.

VULQ1 Programmable Multibeam technology uses software configurable Laser Light Tools to maximize throughput in precision material processing applications.

VULQ1 generates up to hundreds laser beamlets on-demand, from one single laser beam.

The beamlets characteristics are individually and dynamically controlled by software – in position, profile and energy – to create the “Laser Light Tool” fitted to the process needs.

The many beamlets composing the “Laser Light Tool” are applied simultaneously to the material, scaling up process throughput with no compromise on quality.